- HOME

-

About

About

Runfeng Industrial was founded in 1995 and is a scientific, industrial, and trade entity enterprise mainly engaged in silicate materials, providing customers with high-quality solutions.

Explore more >>

-

Products

Silicic acid series

Provide high-performance silicate products in various specifications, including sodium silicate, potassium silicate, etc. Due to its excellent adhesion, heat resistance, and chemical stability, it is widely used in refractory materials, casting, detergents, and chemical industries.

Explore more >>Carbonated series

Focused on producing high-quality carbonate products such as potassium carbonate, sodium carbonate, etc. The product has high purity and good solubility, and is an important basic raw material for glass manufacturing, chemical synthesis, food processing, and cleaning industries.

Explore more >>Water glass series

Produce water glass (sodium silicate solution) commonly known as "foaming alkali". It has excellent bonding, hardening, and anti-corrosion properties, making it an ideal choice for precision casting, building materials, paper industry, ceramics, and soil reinforcement.

Explore more >>Methyl series

Provide a series of organic silicon products mainly composed of methylsilicates. Featuring excellent hydrophobicity, weather resistance, and surface activity, it is specifically designed for high-end applications such as building waterproofing, coating modification, stone protection, and concrete sealing.

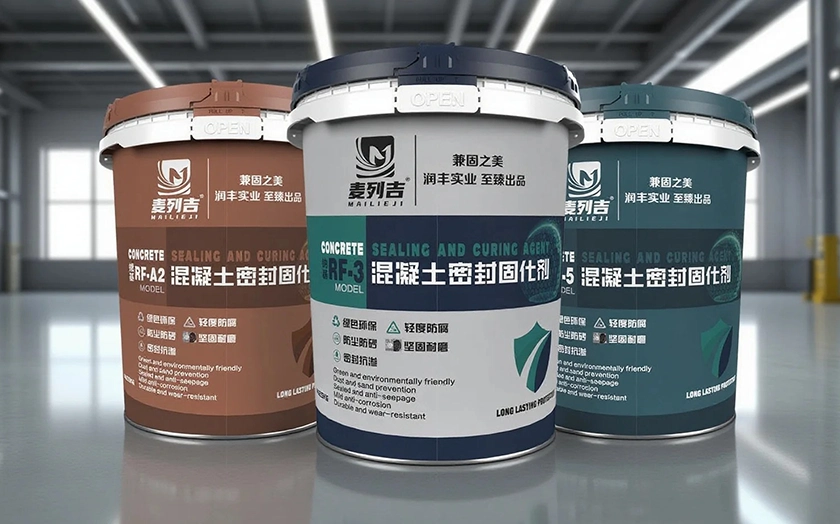

Explore more >>Curing agent series

Develop and produce efficient silicate curing agents (such as sodium silicate and potassium silicate curing agents). It can significantly improve the strength and stability of soil and sand based materials, and is widely used in foundation reinforcement, road construction, and mine backfilling projects.

Explore more >>

-

Media

Media

A comprehensive platform for experts in silicate products to release updates, gather industry information, and participate in exhibition activities.

Explore more >>

- Application cases

-

Service

Service

Quality assurance and technical support are equally important, providing full support for customer needs throughout the process.

Explore more >>

- Faq

- Contact

Potassium silicate for welding rods

2025-06-26

Potassium silicate used for welding rods is a colorless, slightly blue or slightly green, non-toxic, odorless, transparent, viscous liquid or solid. S...

Product Introduction

Potassium silicate used for welding rods is a colorless, slightly blue or slightly green, non-toxic, odorless, transparent, viscous liquid or solid.

Sodium potassium silicate with water glass is one of the main raw materials for producing welding rods, which plays a role in bonding and arc stabilization in the production of welding rods. It is also used as a raw material for fluorescent screen adhesives, precision casting adhesives, coatings, reducing dyes, and silicon compounds. It is a colorless, slightly blue or slightly green, transparent, non-toxic, odorless viscous liquid or solid.

Adhesive used for producing welding electrodes, available in various specifications according to customer needs.

Technical Parameter

| Specification | Modulus (m) | K₂O (%) | Na₂O (%) | SiO₂ (%) | Baumé Degree | Specific Gravity | Viscosity | S (%) | P (%) | Water Insoluble Matter |

| 1:1 Low-Modulus Liquid | 2.5 - 2.7 | ≥5.5 | ≥5.5 | ≥24 | 41 - 43 | 1.400 - 1.424 | — | ≤0.03 | ≤0.03 | ≤0.2 |

| 1:1 High-Modulus Liquid | 3.15 - 3.25 | 4.0 - 6.5 | 4.0 - 6.5 | 27.5 - 31 | 42 - 43 | 1.410 - 1.424 | ≥0.9 | ≤0.03 | ≤0.03 | ≤0.3 |

| 2:1 Low-Modulus Liquid | 2.5 - 2.7 | 8.5 - 11 | 3.3 - 5.5 | 25 - 27 | 41 - 43 | 1.400 - 1.424 | — | ≤0.03 | ≤0.03 | ≤0.2 |

| 2:1 High-Modulus Liquid | 2.95 - 3.05 | 8.0 - 9.0 | 4.0 - 5.0 | 27 - 32.5 | 44 - 46 | 1.438 - 1.468 | ≥0.9 | ≤0.03 | ≤0.03 | ≤0.3 |

| 3:1 Low-Modulus Liquid | 2.5 - 2.7 | 10 - 13 | 2.3 - 4.5 | 24 - 27.5 | 41 - 43 | 1.400 - 1.424 | — | ≤0.03 | ≤0.03 | ≤0.2 |

| 1:1 Double-High Liquid | 2.8 - 3.0 | ≥4.0 | ≥4.0 | ≥26 | 46 - 48 | 1.468 - 1.498 | ≥1.5 | ≤0.03 | ≤0.03 | ≤0.3 |

| 2:1 Double-High Liquid | 2.8 - 3.0 | ≥8.0 | ≥4.0 | ≥27 | 46 - 48 | 1.468 - 1.498 | ≥1.5 | ≤0.03 | ≤0.03 | ≤0.3 |

| 3:1 Double-High Liquid | 2.8 - 3.0 | 10.5 - 12.5 | 2.5 - 4.5 | 29 - 33 | 46 - 48 | 1.468 - 1.498 | ≥1.5 | ≤0.03 | ≤0.03 | ≤0.3 |

| 1:1 Low-Modulus Solid | 2.5 - 2.7 | ≥14 | ≥14 | ≥63 | — | — | — | ≤0.03 | ≤0.03 | ≤0.5 |

| 1:1 High-Modulus Solid | 2.8 - 3.0 | ≥14 | ≥14 | ≥64 | — | — | — | ≤0.03 | ≤0.03 | ≤0.5 |

| 2:1 Low-Modulus Solid | 2.5 - 2.7 | ≥22 | ≥8.0 | ≥62 | — | — | — | <0.03 | <0.03 | ≤0.5 |

| 2:1 High-Modulus Solid | 2.8 - 3.0 | ≥19 | ≥9.5 | ≥64 | — | — | — | ≤0.03 | ≤0.03 | ≤0.5 |

| 3:1 Low-Modulus Solid | 2.5 - 2.7 | ≥25 | ≥6.0 | ≥61 | — | — | — | ≤0.03 | ≤0.03 | ≤0.5 |

| 3:1 High-Modulus Solid | 2.8 - 3.0 | ≥25 | ≥6.0 | ≥63 | — |

Contact us quickly

If you need some help, please ask questions or even provide feedback. Please choose one of the contact methods below and let us know how to provide assistance.