- HOME

-

About

About

Runfeng Industrial was founded in 1995 and is a scientific, industrial, and trade entity enterprise mainly engaged in silicate materials, providing customers with high-quality solutions.

Explore more >>

-

Products

Silicic acid series

Provide high-performance silicate products in various specifications, including sodium silicate, potassium silicate, etc. Due to its excellent adhesion, heat resistance, and chemical stability, it is widely used in refractory materials, casting, detergents, and chemical industries.

Explore more >>Carbonated series

Focused on producing high-quality carbonate products such as potassium carbonate, sodium carbonate, etc. The product has high purity and good solubility, and is an important basic raw material for glass manufacturing, chemical synthesis, food processing, and cleaning industries.

Explore more >>Water glass series

Produce water glass (sodium silicate solution) commonly known as "foaming alkali". It has excellent bonding, hardening, and anti-corrosion properties, making it an ideal choice for precision casting, building materials, paper industry, ceramics, and soil reinforcement.

Explore more >>Methyl series

Provide a series of organic silicon products mainly composed of methylsilicates. Featuring excellent hydrophobicity, weather resistance, and surface activity, it is specifically designed for high-end applications such as building waterproofing, coating modification, stone protection, and concrete sealing.

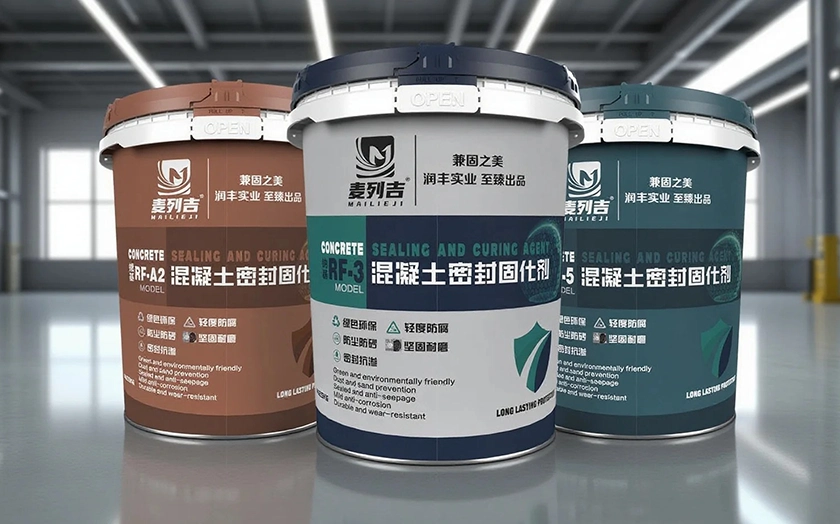

Explore more >>Curing agent series

Develop and produce efficient silicate curing agents (such as sodium silicate and potassium silicate curing agents). It can significantly improve the strength and stability of soil and sand based materials, and is widely used in foundation reinforcement, road construction, and mine backfilling projects.

Explore more >>

-

Media

Media

A comprehensive platform for experts in silicate products to release updates, gather industry information, and participate in exhibition activities.

Explore more >>

- Application cases

-

Service

Service

Quality assurance and technical support are equally important, providing full support for customer needs throughout the process.

Explore more >>

- Faq

- Contact

KP1 adhesive powder

2025-06-26

-

TAG:

- KP1 adhesive powder

Glue can be used for different concentrations of acids such as sulfuric acid, hydrochloric acid, nitric acid, phosphoric acid, acid, hypochlorous acid...

Product Introduction

Glue can be used for different concentrations of acids such as sulfuric acid, hydrochloric acid, nitric acid, phosphoric acid, acid, hypochlorous acid, formic acid, oxalic acid, acetic acid, etc; Multiple organic solvents; Multiple acidic salts; Chlorine gas, hydrogen peroxide, and other oxidizing agents.

Heat resistant and acid resistant adhesive is a new type of anti-corrosion material with pre stress ability composed of potassium silicate as a binder, inorganic polymer materials as curing agents, and silicate aluminum salts as acid resistant fillers. It overcomes the disadvantages of high permeability, low bonding strength, poor water resistance, poor high temperature resistance, and low impact resistance of sodium silicate adhesive.

Cement does not produce salts containing crystalline water in acidic media, thus it has good acid leaching stability. (Fluorinated acids are not resistant)

Room temperature curing, easy to use, easy to transport, moisture-proof storage.

The adhesive adopts non-toxic curing agent, which is non-toxic to operators and construction personnel. It can be widely used in reaction vessels of industrial sectors such as petroleum, chemical, metallurgical, pesticide, food, fermentation hydrolysis, acid washing, etc. In anti-corrosion projects such as storage tanks, tower pools, floors, electrolytic cells, etc.

Technical Parameter

| Property | Unit | Index |

| Density | kg/m³ | 1400 |

| Water Absorption | % | 1-2 |

| Compressive Strength | MPa | 76.1 |

| Tensile Strength | MPa | 8-10 |

| Flexural Strength | MPa | 37.3 |

| Resistance to Potassium Hydroxide | Concentration 40%-55% | Resistant |

| Resistance to Sulfuric Acid | Concentration 80%-98% | Resistant |

| Thermal Conductivity | W/(m·K) | 20.8-23.2 |

| Bonding Strength | MPa | 3-3.9 |

| Linear Expansion Coefficient | 1/℃ | 3×10⁻⁵ |

| Initial Setting Time | h (25℃) | ≥3 |

| Final Setting Time | h (25℃) | ≤12 |

| Service Temperature Range | -35℃-350℃ | Stable |

Contact us quickly

If you need some help, please ask questions or even provide feedback. Please choose one of the contact methods below and let us know how to provide assistance.